First let;s talk a little about English saddles, how they can sore the horse at a sitting trot or walk, even with the best of "fit". How this particular problem could have been prevented with only another hour at the bench.

Just look at where the rear of the sweat flap and outer flap attach to the underside of the tree bar. The two tabs of 1/4" thick leather above the stuffed panels are well hidden where they bend over the sharp angled edge of the tree. NO. 1.... the English tree was never made to fit a horse but shaped to the riders seat. The angles of the tree bars are sharp right up to where they flow into the cantle. (back of the seat) These 2 leather tabs connecting tabs are about 2.5" wide and 1/4" thick apiece and are the extended tabs that attach the sweat and outer flaps of your saddle at the rear. They are nailed to the underside of the bars on each side. Where they curl over that angled thin edge of bar above the stuffed panels, they create a set of Knuckles. Kind of like brass KNUCKS, above your stuffed panels. The top German saddlers are proud to call it necessary for "clear seat aids". While doing clinics in Europe I would palpate a horse at his forward point of the Gluteals & down, at about that suspected spot. Sure enough.... they would dip a foot. (Yes it can be worse on one side than the other.) (READ PG. 6 ) Older horses would be sway backed from this only because of the saddle's "severe seat aids". Croups flatten, backs dorsiflex, heads pop up, all because of this cheap method of saddle production. (Not that this is the only factor, there's still the points of the bars & soring at the withers.) Why are they there, don't these saddlers know what they are doing? ? Yes they know, but this is production saddlery!!! To remedy this problem in a saddle, you take each of the two layers of the flap's leather tabs ( about 3/8" thick total) and cut them into fingers like the top of a castle. Then these two layers must be offset so the fingers make only one layer of leather thickness. This is called "CASTLE CUTTING THE FLAPS. You then skive thin this one layer thickness so as to create a thin layer of top grain leather which attaches the 2 flaps at the rear on each side of the saddle, without the "knuckle" at that curved thin edge of tree bar. How severe are these knuckles above the stuffed panels? When putting the OrthoFlex panels under a UK made saddle without the stuffed panels, these Knuckles would sore the horse right thru the delrin panel. So what can restuffing do with a saddle made like this? Nothing because the knuckles are still there unless the saddle is disassembled. Re-balancing the rider as that's all re-flocking was ever meant to accomplish! To actually fit a horse by re-flocking requires new leather patterns for the stuffed panels. New Panel patterns can then be flocked very firmly to match that horse's back while standing? All of this cost more than buying a new saddle.It still hasn't addressed the problem of the "seat aids" designed to overcome saddle discomfort with MORE PAIN FOR CLEAR SEAT AIDS!! That's Passier's excuse for the knuckles folks. So what is a Master saddler? Simply a good leather craftsman, these people seldom ride. They wouldn't know when a rider was balanced in a saddle if they were there to watch them ride. I've seen few that know the anatomy and physics of movement of the quadruped. I know many of the award winning saddlers in the UK. I've been to their little shops. I've explained as much about saddlery and the horse to them as I could because they couldn't understand why I had to have things done so differently than they were shown. I worked with the treemaker of the UK as well. He's a recluse who seldom goes out in public because of his phobia. He's very quiet and won't even go out to eat. Kevin inherited the business you know! If he doesn't make the tree, he sells the Steel arch stampings to a saddle company that laminates the layers of beech veneer in a simple mold & rivets it to the arched head stampings. That's English saddlery and glimpse of saddle making in the UK. Len > 816 806-4742

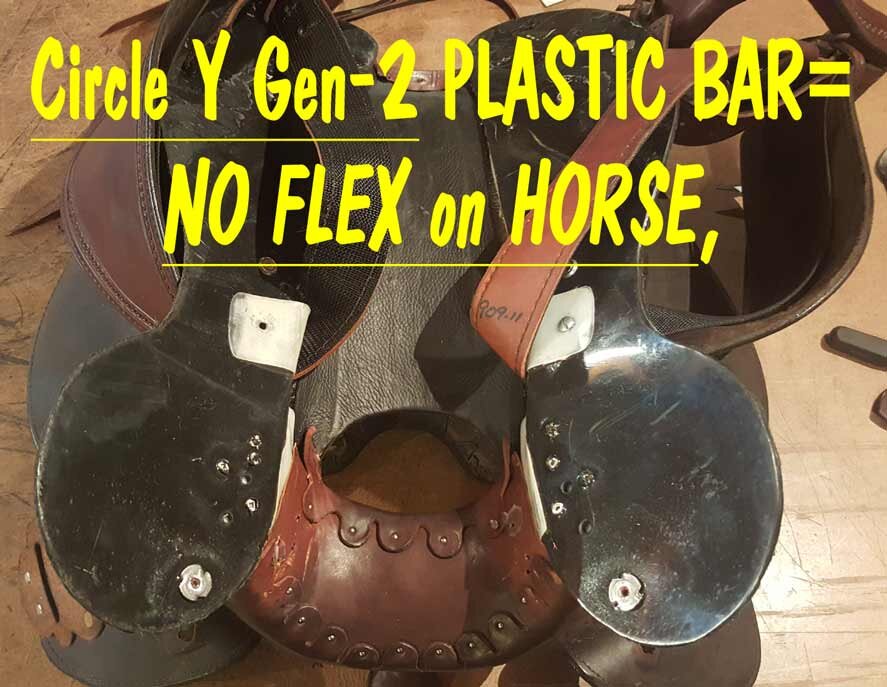

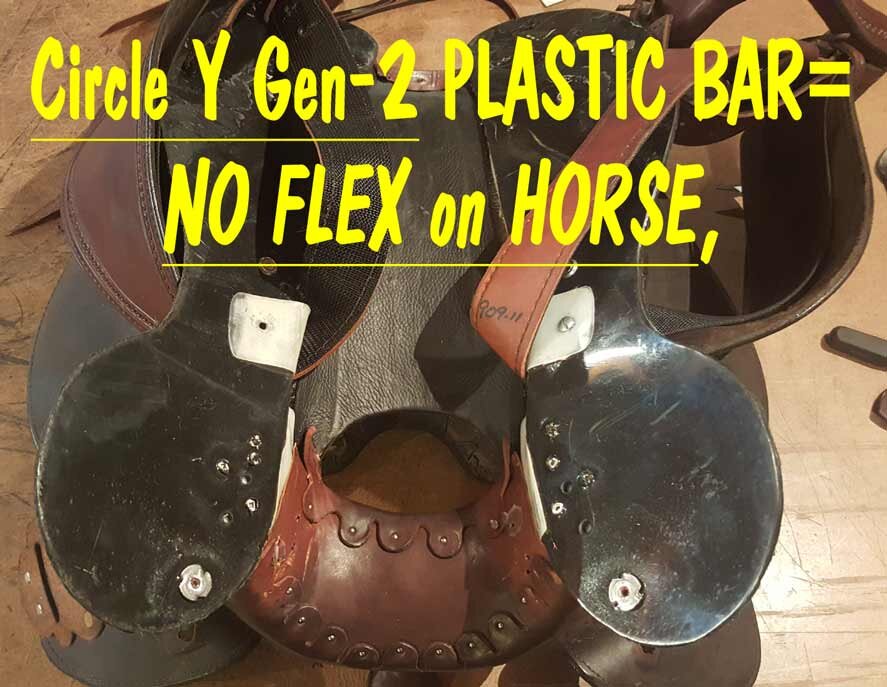

Now let's talk about a banker that met the daughter of an old boy that started a saddle company with a few other guys in Texas. The Banker was a big guy & paid me a grand once to put the ortho system in his saddle. He complained about paying a royalty to a patent owner of a TREELESS saddle he built and sold and used the Circle ? name on it. He later came up with the first flextree saddle. Just 2 thick plastic bars bandsawed out & stapled to a fork & cantle. NO rawhide covering necessary, just a little neoprene foam glued to the bottom of those bars & a slotted fiberglass ground seat to let it bend in one place. The foam wears out, the plastic edges are severe, the bend is in one place, right in front of the cantle. Let this baby hit your horse's back in a barrel run! Yep, just add the name flex & double the price with a top competitors name on it. It's almost as severe as the halftree, not quite, and he didn't have to pay anymore royalties. He saw the handwriting on the wall, sold the whole shebang to an Investment banker from back east that was rolling up a lot of companies (english & western). The venture capitalist went broke buying these companies with these "hot products". They only lasted a few years. Everything was sold again at a big loss to another saddlemaker who had done well with the Tucker saddle in the trail riding field. The only one who made out here was the banker! Circle WHO? His brother-in-law moved to the other side of Yokum and started another saddlery. He's making some serious roping and barrel racing saddles; double j?